Technology applicable to various industrial fields of thermal spray coating business

including fabrication, machining and coating of semiconductors/display ESC and parts

Ceramic coating

- Ceramic coating CERAMIC COATING

- Plasma spray coating technique mainly applies on precise coating with thermal energy of high temperature at high speed. The technique is typically used for material coating with ceramic-series coating powder.

Ceramic coating material

Ceramic coating material with excellent properties of ceramic materials is used mainly for the purposes of abrasion resistance, corrosion resistance, oxidation resistance, heat transfer, and electric insulation. All of powdered materials that can be molten (e.g., ceramic and metal powder) are used in diversified fields of industries such as:

Applicable fields

Electronics, textile, heavy industry, shipbuilding, aviation, aerospace, and automobile.

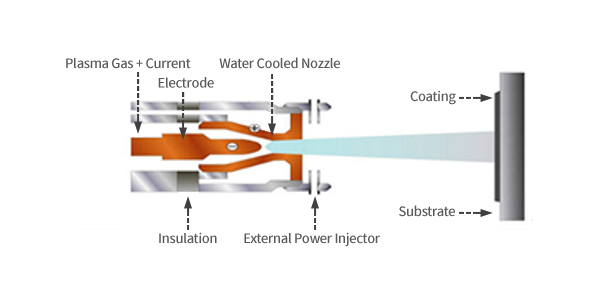

Plasma spray process

- Electric energy of low voltage and high current from DC +, - charged cable ionizes inert gas to generate plasma.

- Forming dense coating film with thermal energy of high temperature, and velocity energy of high speed (16,500┬░C)

Y2O3 Powder

Y2O3 powder has stability for corrosion- and oxidation-resistance, and properties of the powder vary upon purity. The main industrial application is light emitting diode (LED) or phosphorescent body, and particularly, the powder is used as red phosphorescent body of cathode ray tube (CRT) display. The powder is used for producing electrode, electrolyte, laser and superconductor. Y2O3 Powder is fabricated with ball mill engineering.

YAG Powder

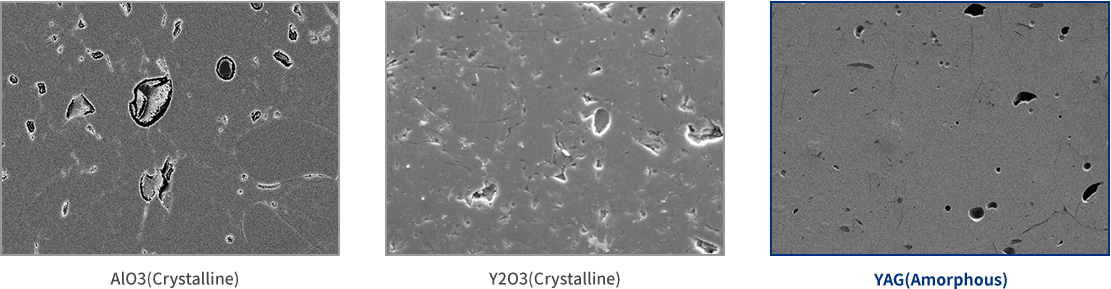

Yttrium Aluminum Garnet (YAG) powder has high resistance against abrasion, corrosion and chemicals when film is formed by spraying the powder in plasma form at temperature of approx. 12,000┬░C. Properties of YAG powder are far significantly superior to Al2O3 or Y2O3 that have typically been used for semiconductor and LCD system parts.

While film formed with Al2O3 or Y2O3 is of crystalline structure, film formed YAG is of amorphous structure. YAG powder is manufactured of Al2O3 and Y2O3 at ratio of 4.5:5.5 with ball mill engineering.

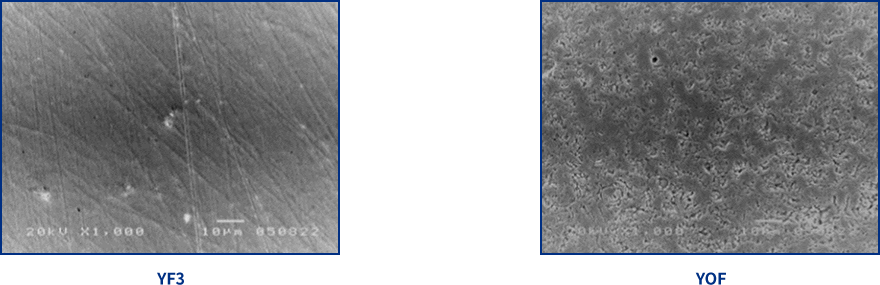

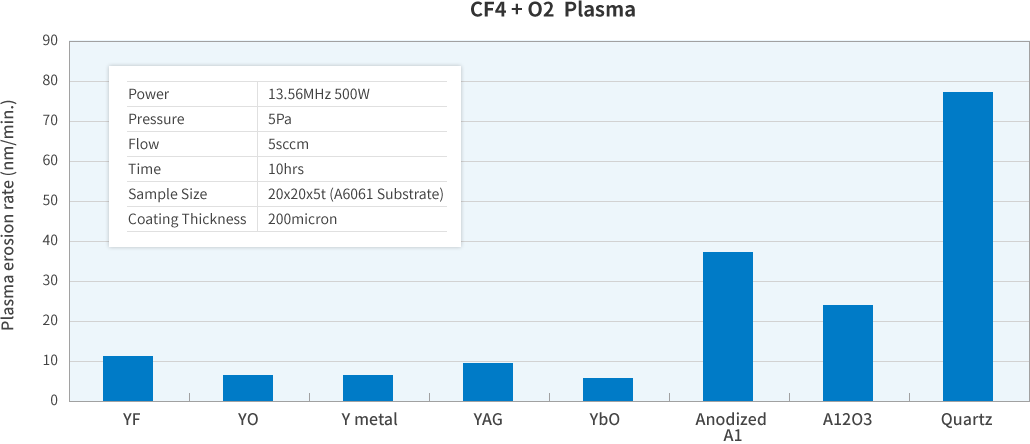

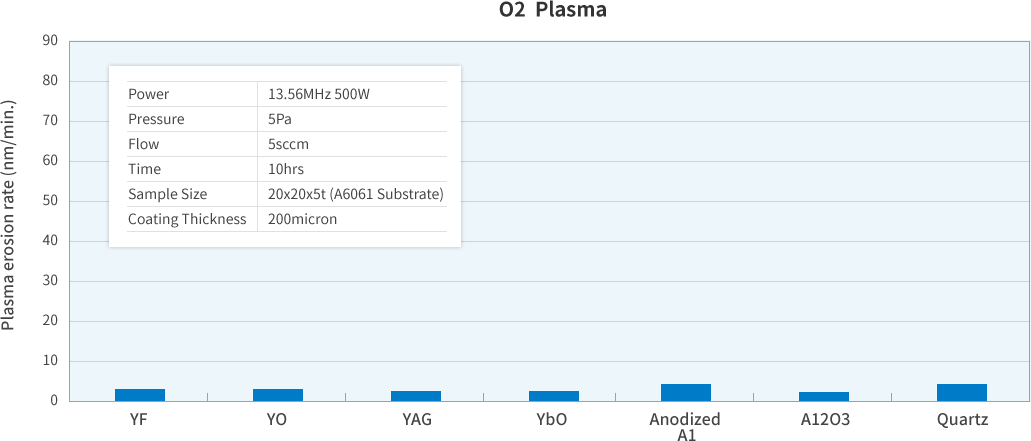

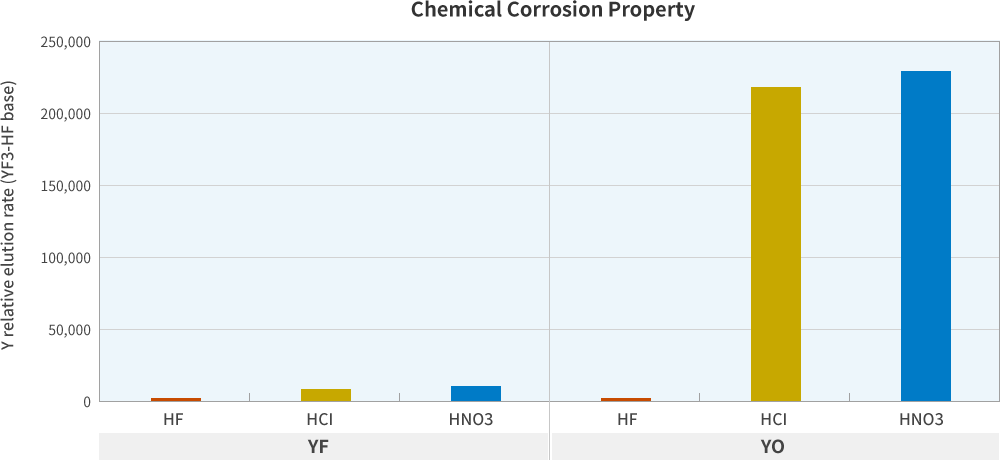

YF3 & YOF Powder

YF3 and YOF improve properties of Y2O3 to enhance resistance against corrosion and oxidation. YF3 and YOF powder are produced with ball mill engineering together with Y2O3.